| University | Nanyang Technological University (NTU) |

| Subject | CH3121 Chemical Biological & Plant Safety |

Quiz: Source, Dispersion and LOPA Analysis- Individual CA2

- Perform Analysis using Source Model

- Deploy ALOHA software and generate the toxic and dispersion contours.

- Summarize the results and do a comparison through your observation.

- Perform LOPA to develop extra independent protection layer(s)

Problem:

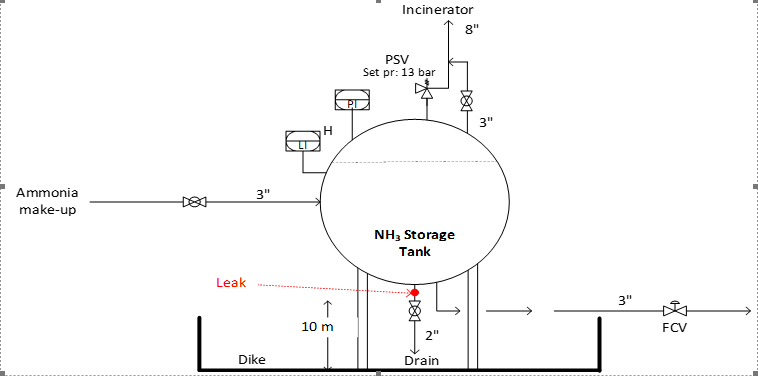

An ammonia storage tank leaks at its bottom piping through an effective opening with a diameter of 50 mm. NH3 is stored under saturated liquid conditions at 11.58 bar and 30oC. Location of leak in piping is at 10-meter elevation above the ground level. Typical details of the NH3 storage tank are shown in the following diagram.

a. Estimate NH3 liquid spill (in kg) collected in the bottom dike in one hour. (Assume (i) steady state between spill rate and evaporation rate. (ii) Evaporation occurs over entire cross section of the dike). Estimate the total NH3 vapor release to air by flashing and evaporation.

NH3 liquid temperature after depressurizing through 50 mm opening to atmospheric pressure (atmospheric boiling point of NH3) = – 33oC

Ammonia liquid density at -33oC = 673.1 kg/m3

Heat of vaporization of NH3 at atmospheric pressure= 1170.87kJ/kg

Difference in specific volume between vapor and liquid NH3= 1.38115 m3/kg

Cp for NH3= 2.103 kJ/kg.K

Dike dimensions: 10m(L) x 10m(B) x 0.6 m(H). (8 Marks)

b. Perform toxic dispersion analysis for released NH3 using ALOHA software. Assume open country conditions and atmospheric stability class B. Wind speed is 2 m/s. Assume a humidity of 80%. Site’s ambient temperature is 30oC. Use ALOHA Gaussian and Heavy gas dispersion models to develop ERPG1, ERPG2 and IDLH risk contours. State any assumptions used in the model. (6 Marks)

c) Perform LOPA and develop an appropriate solution to reduce the NH3 storage tank overpressure frequency to well within the acceptable frequency. Due to changes in NH3 make-up rate (much higher than the original design rate), PSV on top of the NH3 storage tank is under sized. Operator mistake during NH3 make-up can result in overpressure in the tank. State any assumptions used. Use typical PFD (probability of failure on demand) values of protection layers from lecture notes/ textbook or any other reference (If external source of reference is used, please cite it clearly). If SIS (safety instrumented system) solutions are required, develop an SRS (Safety requirement specifications) document. (6 Marks)

Initiating event frequencies for overpressure are:

| Initiating event | Frequency |

| Operator failure | 10-1 per year |

Acceptable overpressure frequency for the site is 10-5 incidents/year.

– submit via “Assignments” portal on Blackboard by 2359 hrs. 7th Nov 202

Hire a Professional Essay & Assignment Writer for completing your Academic Assessments

Native Singapore Writers Team

- 100% Plagiarism-Free Essay

- Highest Satisfaction Rate

- Free Revision

- On-Time Delivery

Struggling with your CH3121 Chemical, Biological & Plant Safety Individual CA2? Get expert guidance from Singapore Assignment Help for ALOHA dispersion modeling, LOPA analysis, and ammonia leak calculations. Our experts deliver precise, plagiarism-free reports with accurate chemical safety assessments. Explore our Chemical Engineering assignment help to connect with trusted SG assignment helper today.

Looking for Plagiarism free Answers for your college/ university Assignments.

- EE4524 Design of Clean Energy System Assignment Questions 2026 | NTU

- PSY107 Introduction to Psychology 1 Tutor-Marked Assignment 02 2026

- BPM213 Procurement Management Tutor-Marked Assignment One 2026 | SUSS

- ICT330 Database Management Systems Tutor-Marked Assignment Questions 2026

- 7WBS2009 Financial Management and Analysis Assignment Brief 2026 | SUSS

- 5010MKT Marketing Management Assignment Brief 2026 | Coventry University

- FILM1000 Introduction to Film Studies Assignment Brief 2026 | NTU

- CET206 Full Stack Web Application Development Tutar Marked Assignment Questions 2026 | SUSS

- 7WBS2011 Strategic Management Research Assignment Brief 2026 | PSB Academy

- HBC101 Understanding Contemporary Society: The Social and Behavioural Sciences TMA 01 2026 | SUSS